The Of Premier Aluminum Llc

The Of Premier Aluminum Llc

Blog Article

The 9-Second Trick For Premier Aluminum Llc

Table of Contents8 Simple Techniques For Premier Aluminum LlcSome Known Facts About Premier Aluminum Llc.Little Known Facts About Premier Aluminum Llc.Some Known Factual Statements About Premier Aluminum Llc Not known Facts About Premier Aluminum Llc

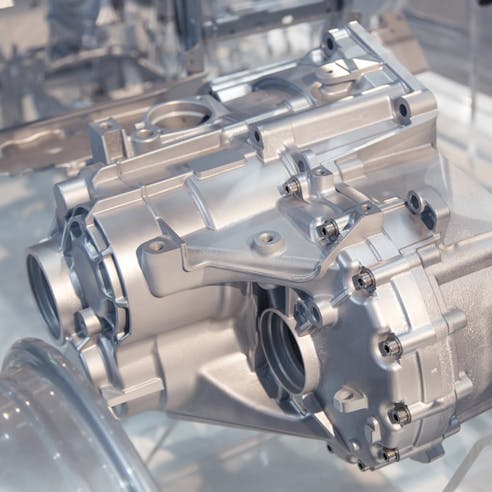

When choosing a light weight aluminum foundry for your manufacturing demands, it's critical to examine a number of variables. Among one of the most vital aspects to think about is the experience and competence of the foundry. Selecting a factory who has the appropriate knowledge of the aluminum casting process, and the profile to reveal for it, helps to have an effective result for your job.Having the experience and market understanding to engineer your castings for optimal manufacturing and top quality end results will improve the job. Producing aluminum spreading calls for a facility collection of processes to accomplish the appropriate outcomes. When selecting a new aluminum shop to partner with, ensure they have substantial market experience and are knowledgeable about all aspects of the light weight aluminum casting process: style, production, material analysis, and item screening.

The foundry ought to additionally have a proven track record of providing extraordinary items that satisfy or exceed customer assumptions. Quality control should additionally be at the top of your list when picking a light weight aluminum factory. By dealing with a certified foundry that adheres to the requirements for high quality control, you can safeguard the stability of your product and ensure it fulfills your specifications.

Little Known Questions About Premier Aluminum Llc.

Different parts that extremely made complex shapes can be produced using this procedure. Before you begin looking for a trustworthy aluminum die wheel, there are some important points that you require to do.

You have to ask yourself what kind of aluminum die castings you need. After determining what you need, you need to specify the requirements of the aluminum die castings you call for. Identify the weight, thickness, size, and various other specifications of the light weight aluminum die-cast you call for. It would certainly likewise be a lot better if you can attract and show all the dimensions of the aluminum die-cast.

After having this details, you can start investigating light weight aluminum die-casting makers. You can do this by merely keying the search phrase" Light weight aluminum die casting suppliers" on the Google search engine.

Some of the concerns you require to ask yourself are whether they have experienced and trained drivers, for how long their service has functioned, or if they have some success. You can usually obtain the solution to these inquiries from the producer's internet site. You can look into other sites or external resources to validate if the info provided on the manufacturer's internet site is authentic.

What Does Premier Aluminum Llc Mean?

One more point you have to think about is the producer's capability to create light weight aluminum die-casting products. Simply put, the volume of products the maker can generate at an offered time. Some of the critical inquiries you need to ask yourself are click over here now whether the manufacturer can generate a higher quantity or can the manufacturer fulfill your demands.

(https://sketchfab.com/premieraluminum)What if your business calls for 10,000 pieces of certain machine parts from the producer within one month? You ordered this quantity; nevertheless, the supplier can just create 5000 items of these equipment parts within one month (Foundry near me). As a result, you will not be able to obtain the amount that you get on time

Premier Aluminum Llc Can Be Fun For Anyone

Thus, it is essential that you need to ask if the manufacturer is applying an internal tooling process. In addition, you have to ask the manufacturer exactly how much the cost of internal tooling is. The internal tooling process, which permits you to develop distinctive layouts and shapes can be an additional cost.

This element straight associates with the manufacturer's manufacturing capability. You have to try to find a producer that can make sure quicker shipment of items. However, this should be carried out in such a way that high-grade standards are kept. This can guarantee that you can obtain your products on time, and you can prevent missing those important organization possibilities.

This means that there are a number of alternatives that you can choose from. Today, client needs keep altering. It seems that consumers are looking for a superb mix of high quality, cost-effectiveness, and resilience. That is why it is substantially suggested that you ought to choose a manufacturer that can produce different kinds of aluminum die-cast items.

The Only Guide for Premier Aluminum Llc

Many commonly, these light weight aluminum die-casting items will certainly need some styles, machining, or finishing touches. Having this in mind, you ought to seek a manufacturer that can perform a range of secondary ending up works once pass away casting is done. Some examples of finishing procedures consist of Chromating, CNC Machining, Sandblasting, Powder finishing, Anodized, E-coating, Wet painting, Plating, and much more.

Die spreading is one of the most affordable, accurate, and protean manufacturing procedures on the planet moment. The process includes suitable molten essence, under stress, into a suitable die (earth), and previously solidified it can be ejected and completed (if necessary) in a range of ways. The passes away are [...]. Report this page